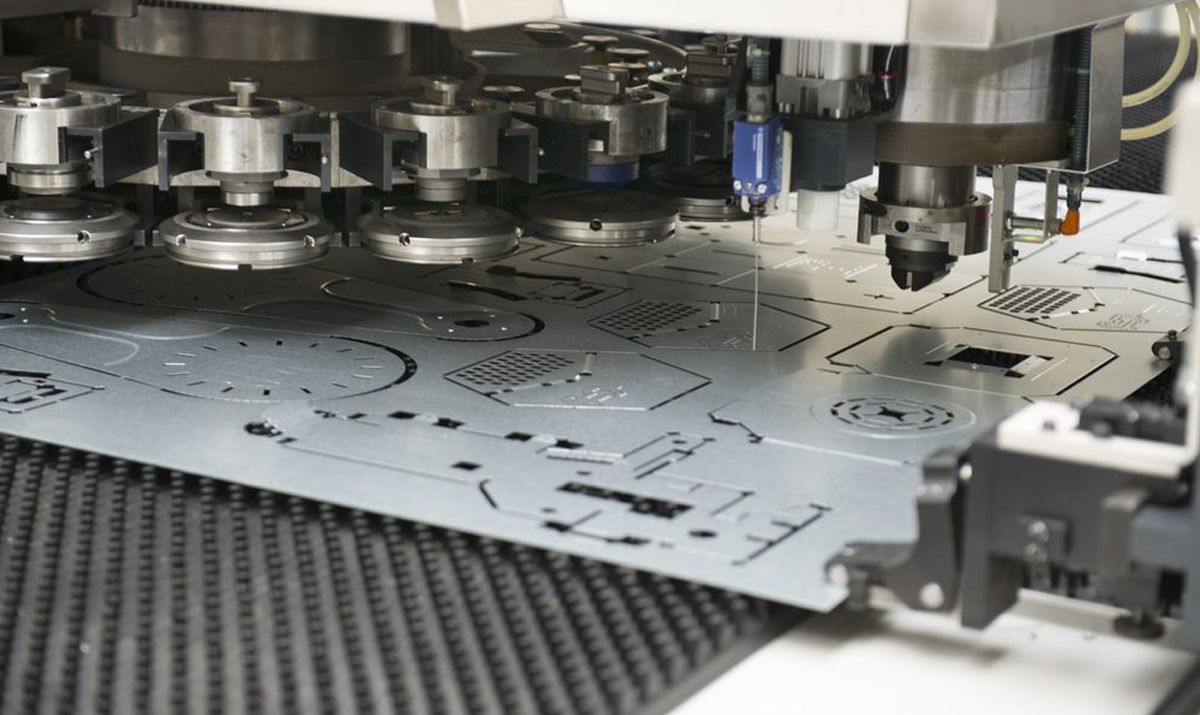

Turret punching is a versatile and efficient sheet metal fabrication process used to create a wide range of hole patterns, shapes, and profiles in metal sheets. It involves a machine known as a turret punch press, which has a rotating turret that holds a variety of punching tools, including round punches, rectangular punches, and forming tools. The process begins with the operator or a computer-controlled program positioning the metal sheet on the machine's worktable. The turret punch press then selects the appropriate tool from its turret and precisely punches through the metal sheet, creating holes or shapes according to the programmed design. Turret punching offers rapid production speeds, high accuracy, and the ability to create intricate patterns, making it a popular choice in industries such as manufacturing, electronics, and automotive, where precision sheet metal components are essential for various applications.

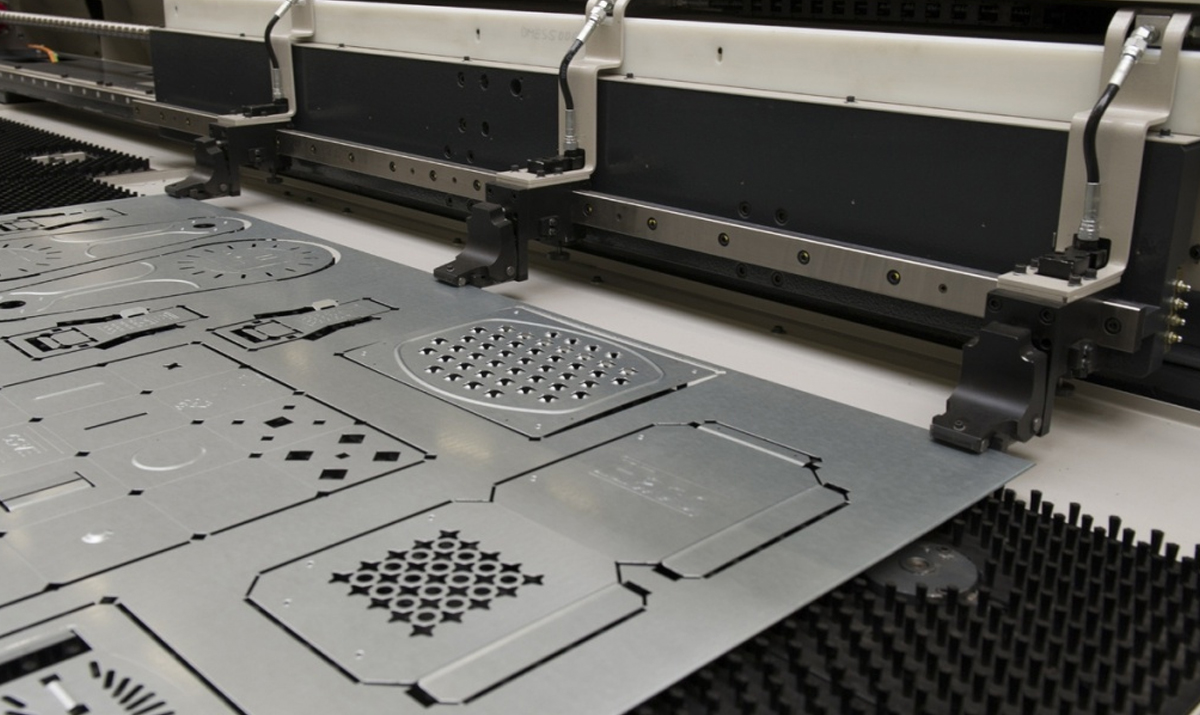

Metal punching is a metalworking process used to create holes, shapes, or patterns in sheet metal and other metallic materials. It involves the use of a mechanical or hydraulic punch press, which exerts significant force to push a punch through the metal, thereby forming a hole or cutting out a specific shape. The punch itself is often made of hardened steel and is designed to match the desired hole size or shape. Additionally, a die is used on the opposite side of the metal to support it during the punching process, ensuring clean and precise results. Metal punching is widely employed in various industries, including manufacturing, automotive, construction, and electronics, for applications ranging from creating ventilation holes in metal panels to producing intricate designs in decorative metalwork. It offers an efficient and cost-effective means of metal fabrication, particularly when high volumes of components with consistent shapes and sizes are required.

Steel punching is a metal fabrication process that involves creating holes or openings in steel sheets, plates, or structural components. This method typically employs a hydraulic or mechanical punch press equipped with specialized tooling, which exerts significant force to pierce through the steel material. The tooling can be customized to produce holes of varying sizes and shapes, making it a versatile technique for various applications, such as creating openings for bolts, rivets, or other fasteners, as well as for ventilation, drainage, or decorative purposes. Steel punching offers several advantages, including speed, precision, and cost-effectiveness when compared to other cutting methods like drilling or milling. It is commonly used in industries like construction, manufacturing, and metalworking, where accurately placed holes in steel components are essential for structural integrity and functionality.