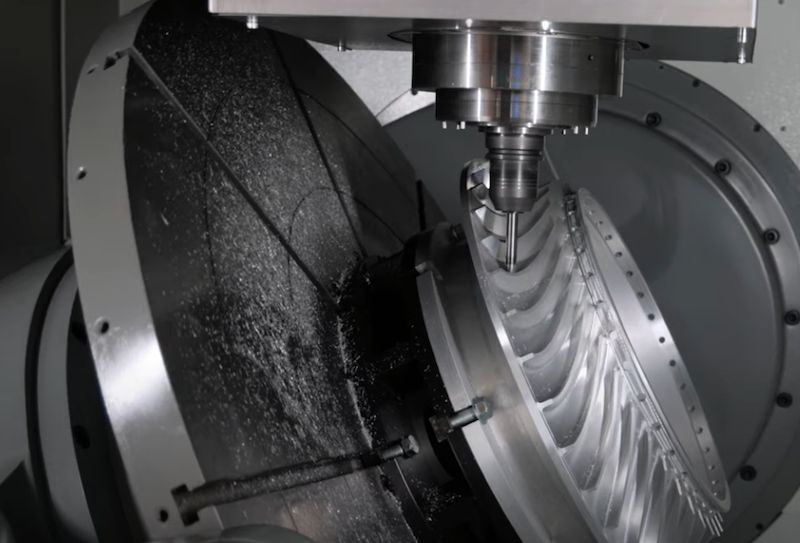

CNC machining is poised to unlock new possibilities in terms of material capabilities, design flexibility, and automation, thereby reshaping the landscape of advanced manufacturing. This technology's potential extends beyond its current applications, promising to drive innovation and efficiency in the production of tomorrow's products.

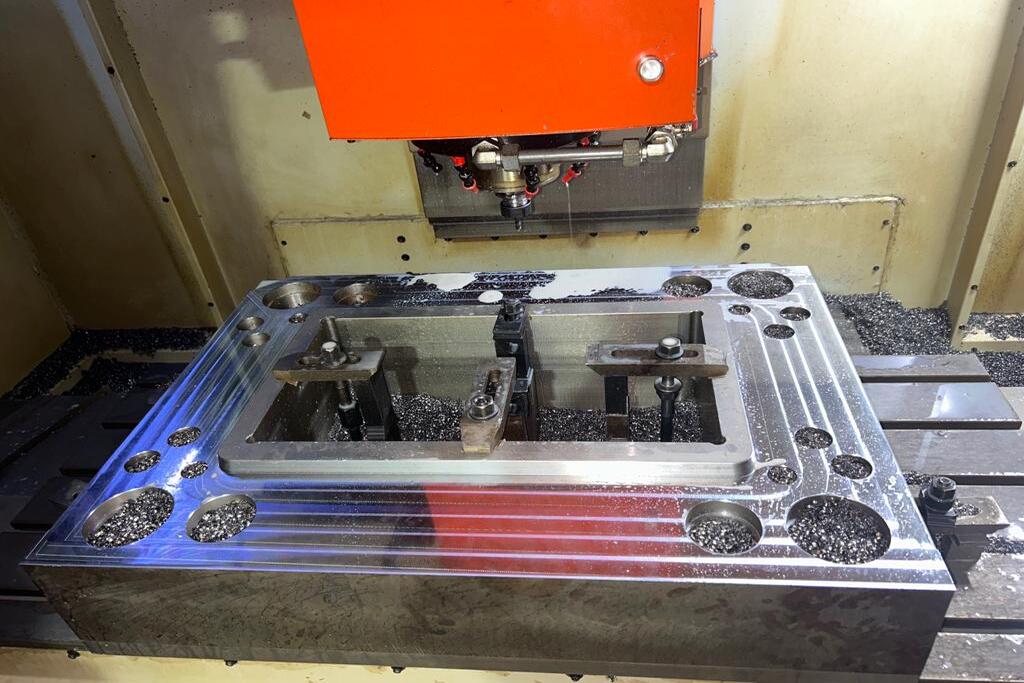

Precision machining solutions represent a pivotal bridge from prototype development to high-volume production in the manufacturing world. These solutions offer a seamless transition for businesses looking to bring their innovative ideas to life while maintaining the capacity to scale up efficiently. Starting with prototypes, precision machining allows for the creation of intricate, highly detailed components with exceptional accuracy. This precision is crucial in the early stages of product development, enabling designers and engineers to refine their concepts and assess functionality.

One of the key advantages of CNC machining for complex parts is its repeatability. Whether producing a single prototype or scaling up to high-volume production, CNC machines consistently deliver parts with the same level of precision. This reliability is invaluable in industries where safety, functionality, and performance are paramount.