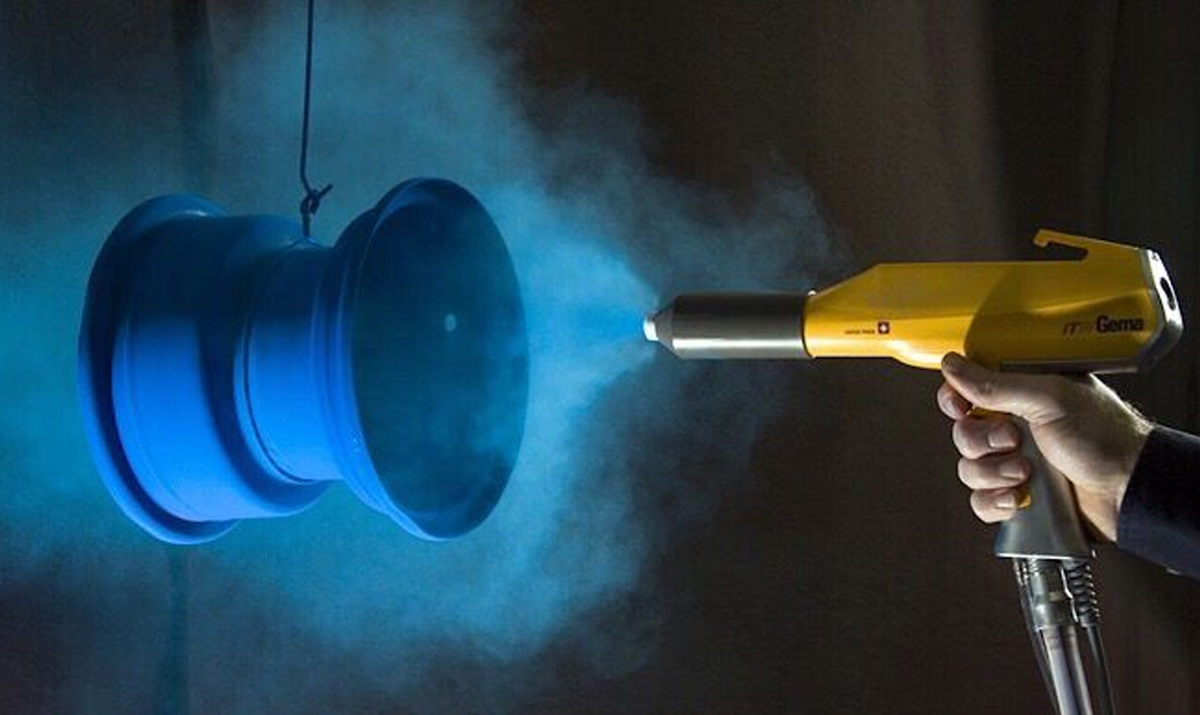

Powder coating is a widely used finishing process in which a fine, dry powder made of pigment and resin is applied to a surface, typically metal, to create a durable and attractive finish. This process involves three main steps: first, the powder is electrostatically charged and sprayed onto the object, causing the particles to adhere to its surface. Next, the coated object is heated in an oven, where the powder melts and fuses into a smooth, uniform layer. During this curing process, the powder chemically reacts to form strong bonds, resulting in a robust and corrosion-resistant finish that is resistant to chipping, fading, and other forms of wear and tear. Powder coating is commonly used in various industries, including automotive, furniture, appliances, and architectural applications, due to its environmental friendliness, durability, and ability to produce a wide range of colors and textures.

Metallic and texture powder coatings are two distinct types of finishes used in the field of industrial coatings and metal finishing. Metallic powder coatings incorporate metallic pigments or flakes into the powder coating formulation, resulting in a reflective and lustrous finish that mimics the appearance of metals like silver, gold, or bronze. These coatings are often chosen for their decorative and aesthetic appeal, adding a touch of sophistication and depth to surfaces. On the other hand, texture powder coatings create a tactile and visually interesting surface by incorporating various additives into the coating that produce a textured or rough finish. These textures can range from fine-grain patterns to more pronounced textures, offering not only a unique appearance but also functional benefits like improved grip or durability. Both metallic and texture powder coatings are popular choices in industries such as automotive, architecture, and furniture manufacturing, where enhancing the visual and tactile qualities of metal surfaces is essential.

Powder coating is a widely used finishing process in which a fine, dry powder made of pigment and resin is applied to a surface, typically metal, to create a durable and attractive finish. This process involves three main steps: first, the powder is electrostatically charged and sprayed onto the object, causing the particles to adhere to its surface. Next, the coated object is heated in an oven, where the powder melts and fuses into a smooth, uniform layer. During this curing process, the powder chemically reacts to form strong bonds, resulting in a robust and corrosion-resistant finish that is resistant to chipping, fading, and other forms of wear and tear. Powder coating is commonly used in various industries, including automotive, furniture, appliances, and architectural applications, due to its environmental friendliness, durability, and ability to produce a wide range of colors and textures.