Laser cutting is a precise and versatile manufacturing process that utilizes a high-powered laser beam to cut through a wide range of materials with exceptional accuracy and speed. It operates by focusing the laser's energy onto a specific point, melting, burning, or vaporizing the material at that location, and then moving the laser beam along a predefined path to create intricate and precise cuts. Laser cutting is commonly used in various industries, including automotive, aerospace, electronics, and crafts, to produce intricate shapes, patterns, and custom designs in materials such as metal, wood, plastic, and fabric. Its ability to provide clean edges, minimal heat-affected zones, and intricate details makes it a popular choice for both industrial and artistic applications.

Metal laser cutting is a highly precise and efficient manufacturing process used in various industries, including automotive, aerospace, and sheet metal fabrication. It involves the use of a high-powered laser beam, typically CO2 or fiber lasers, to precisely cut through metal sheets or components. The focused laser beam generates intense heat, melting or vaporizing the metal in a controlled manner, while a computer-controlled system guides the laser to create intricate and precise cuts. This technology offers several advantages, including minimal material waste, high cutting speeds, and the ability to produce complex shapes and fine details. Metal laser cutting is widely favored for its accuracy and versatility, making it an essential tool for modern manufacturing and fabrication processes.

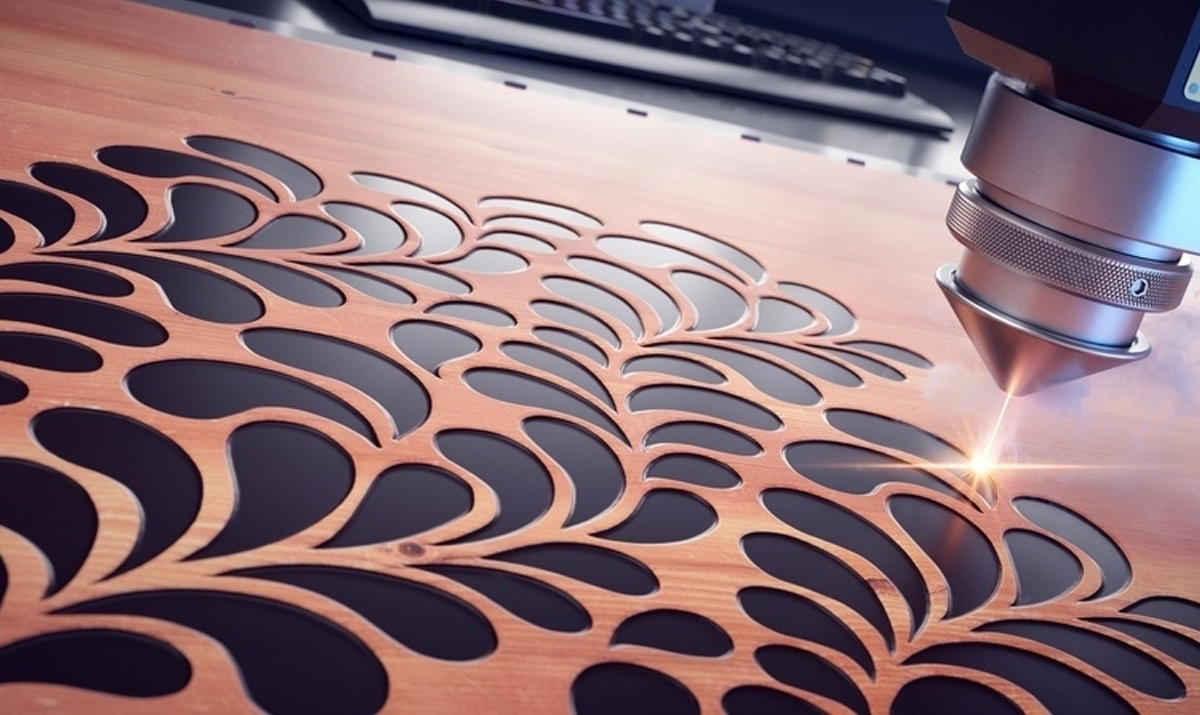

Wooden laser cutting is a precise and versatile manufacturing process that uses a high-powered laser beam to precisely cut and engrave wood materials. It offers numerous advantages, such as the ability to create intricate designs, sharp edges, and smooth finishes on various types of wood, including plywood, MDF (medium-density fiberboard), and hardwoods. The laser cutter operates by focusing the laser beam on a specific area, which generates intense heat and vaporizes or burns away the wood, leaving behind the desired pattern or cutout. This technology is widely used in various industries, including woodworking, crafting, and signage production, as it allows for rapid prototyping and customization, making it an excellent choice for creating intricate wooden designs with precision and efficiency